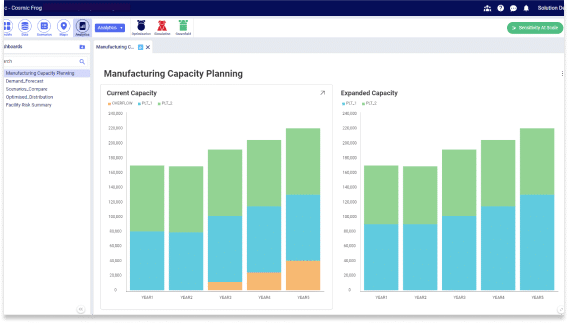

Manufacturing Capacity Planning

Optimize production plans to meet current and future demand

![SCOA_2014_3Line_RGB_72DPI_BlackType[1] SCOA 2014 3Line RGB 72DPI BlackType1](https://optilogic.com/wp-content/uploads/2023/12/SCOA_2014_3Line_RGB_72DPI_BlackType1.png)

Manufacturing Capacity Planning with Cosmic Frog

Manufacturing capacity planning uses optimization and simulation modeling to determine how resource allocation and distribution will impact supply chain efficiency.

With Cosmic Frog manufacturing capacity planning you can understand current production capacity needs while forecasting future requirements and risk factors.

Enter data on your facilities, production lines, and processes to identify your baseline

Model a variety of what-if scenarios to optimize production capacity

Get a risk rating with every scenario

Optimize Resource Utilization to Unlock Hidden Capacity

Manufacturing capacity planning software helps you create efficient production planning schedules that minimize the over and underutilization of resources based on historical data, current demand, and production capabilities. This enables tactical, shorter-term planning that maximizes existing capacity and determines how you will use excess inventory that doesn’t fit in the warehouses.

Streamline Your Capacity Planning Process

Find out when, where, and how to make or buy products

Avoid expedited scheduling, excess in-process inventory, missed delivery dates, and unhappy customers

Boost efficiency, delivery capacity, and profit margins

Align Supply and Demand to Maximize Actual Output

Create models with variable demand to identify strains in your production capacity planning process, then adjust production accordingly. Balancing supply and expected demand improves customer satisfaction and supply chain performance by eliminating problems like stockouts, excess inventory, and holding costs.

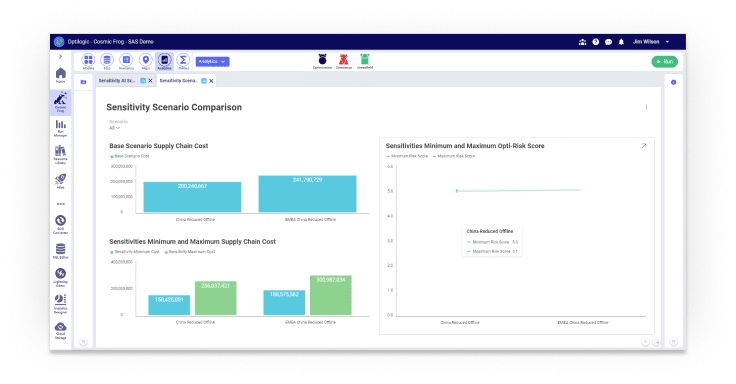

Manage Risk with Scenario Simulation

Model “what-if” scenarios that reflect changes in forecasted demand, production capacity, or lead times, then use these simulations to identify potential bottlenecks, constraints, and other risks and create contingency plans before they become supply chain disruptions. Determine the root cause and best mitigation strategies by running an iteration of the simulation for each potential mitigation strategy.

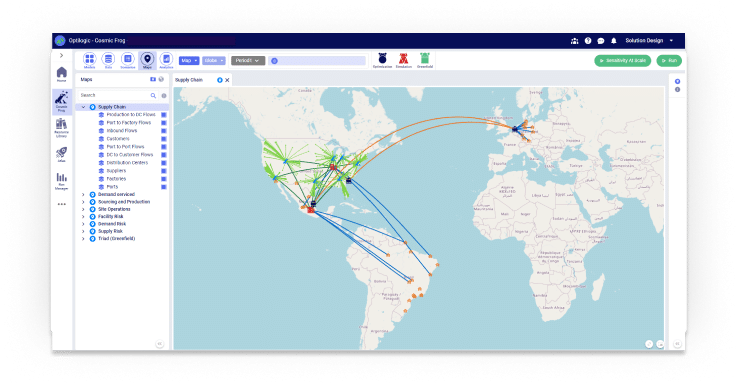

Cosmic Frog Analyzes 1000s of Future-State Supply Chain Scenarios in Minutes

Watch a 5-minute demo of Cosmic Frog

Cosmic Frog Manufacturing Capacity Planning Features

Intelligent Greenfield Analysis

Balance demand, capacity, cost, and risk to determine ideal locations for sustainable, resilient production.

Simulation modeling

Include different future supply chain configuration and the financial implications of each of them with Optilogic’s Intelligent Greenfield Analysis.

Risk rating

Cosmic Frog includes a risk rating for every simulation run, informing capacity planning strategy and empowering you to incorporate risk into your organization’s supply chain processes and build a strong supply chain network.

Hyper-scaling

Use Cosmic Frog’s fully cloud-based modeling studio to run 10, 100, or 1,000 scenarios simultaneously without tying up local computer power. Cloud computing capabilities also streamline collaboration between consulting partners, suppliers, and other stakeholders.

Include inventory and plan for storage capacity

For investments in new storage facilities, leverage our inventory solution and understand the implication of the capex decisions in cash flow delivered from the stock level.

Get a risk rating on every CapEx scenario

Cosmic Frog’s risk engine assigns an OptiRisk score for every scenario to help you make smart decisions that increase supply chain resilience.