Answering All the Questions, at Scale: PECO Pallet Supply Chain Model Conversion Project

When PECO Pallet converted its supply chain model to Optilogic, the company saw a marked improvement in solve times and complex analytics.

When PECO Pallet entered the supply chain services market in the late ‘90s, the founders were intent on improving on a foundational element of how supply chains function: the simple pallet. The prevailing pallet supplier routinely sacrificed good service and quality, taking shortcuts and leaving customers dissatisfied.

PECO’s unique offering — pallets free from chemical and hazardous materials and kiln-dried to control infestation, mold, and moisture — has proved attractive to producers and suppliers all along the supply chain, fueling the company’s ability to scale in a competitive industry.

Over time, PECO has scaled dramatically, increasing client volume and acquiring larger clients and amassing a huge pallet inventory. Today, the company operates throughout North America and manages an ever-growing store of pallets as they move throughout supply chains across much of the continent.

|

However, the supply chain modeling tools PECO had been using to optimize efficiency were becoming too limiting. The company wanted much more granular control and felt the growth of the company — including the inherent complexity of PECO’s operations — had outpaced the computational abilities of its legacy software solutions.

PECO was searching for a solution to mitigate several key issues:

- Aggregated, generalized analytics that didn’t provide enough insight

- Modeling on hypothetical scenarios was taking far too long and limiting scope

- Desktop-based software that didn’t work well online or in the cloud

The Optilogic Solution

PECO partnered with network optimization experts at Optilogic to fine-tune its supply chain model in an innovative way. PECO is unique from other producers in that they need to manage many thousands of units under a single SKU, a characteristic Optilogic considered carefully.

AI-driven Optilogic is purpose-built to analyze a myriad of supply chain questions, such as:

- Where are my weak points?

- Where are my strengths?

- Is my supply chain strong enough to survive another pandemic?

- Do I have solutions and backup solutions for every potential threat scenario?

By modeling on constraint scenarios, Optilogic can achieve higher fidelity optimization results. Optilogic is adaptable enough that the platform was able to decouple (break up or segment) large PECO models to feed them back into the company’s computing infrastructure.

Optilogic proposed a 3-step process focused on improving time to solve, granular analysis, and collaborative outputs:

-

Conversion to Optilogic format (mapping data tables to Optilogic, migrating data into Optilogic database), followed by model validation and testing.

-

Fixed and variable costs added to Optilogic and concurrent scenarios executed in Optilogic’s hyperscale environment. Optimized data exported to reporting tools.

-

Verifying scalability improvements to improve build times, and finally, quality assurance steps to ensure directionally correct results when compared to previous results.

Models and results would be uploaded directly into the cloud, where collaboration via Atlas, Optilogic’s Integrated Development Environment (IDE) can occur.

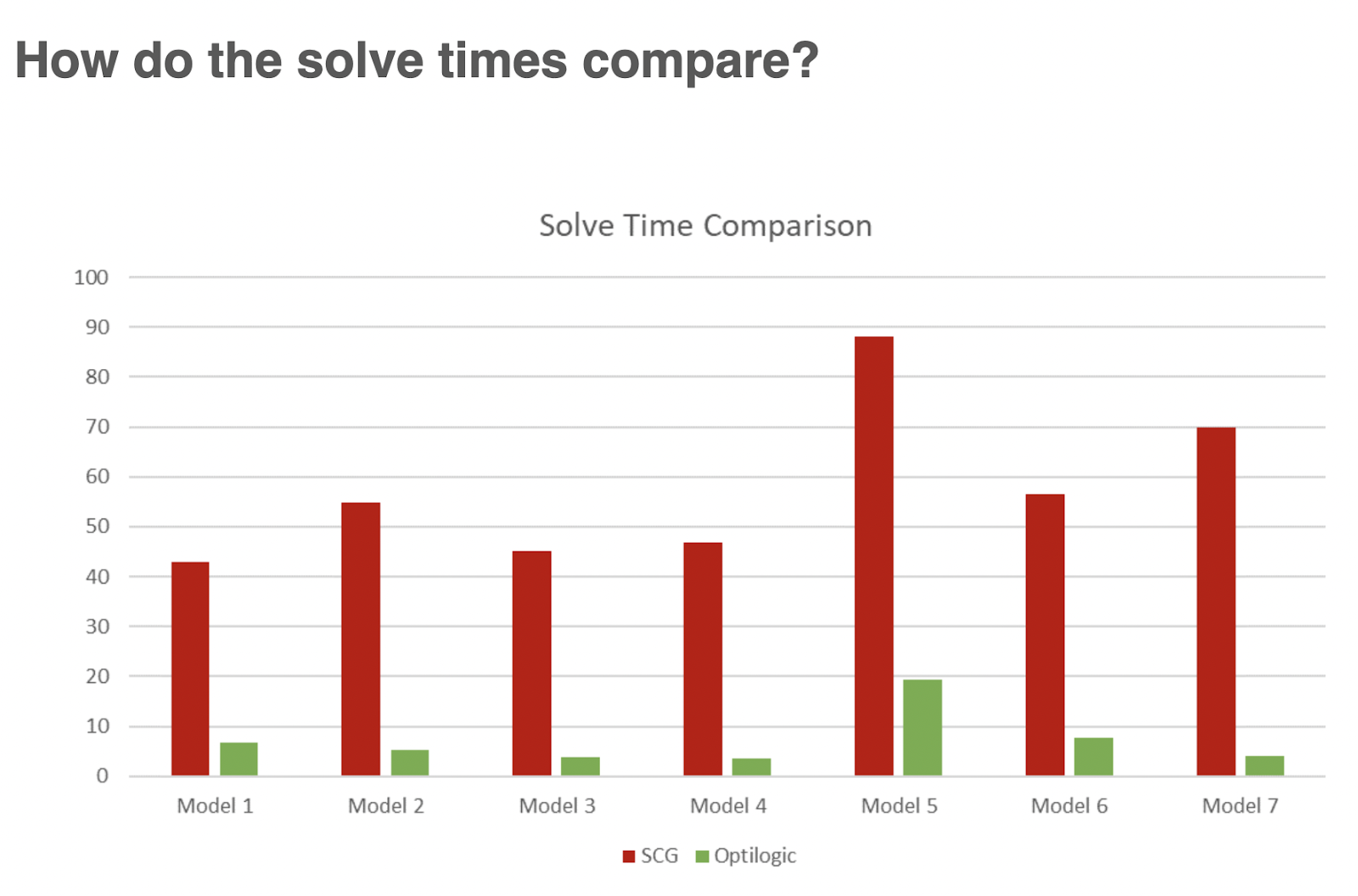

The results have been game-changing. With Optilogic, solve times are at least 5X faster than other Supply Chain Design solutions.

In addition, PECO no longer needs to go back to their previous technology to make various model changes. For example:

-

Adjusting capacities

-

Opening and closing nodes

-

Adjusting supply and demand

-

Adjusting inventory policies

Because Optilogic is able to solve in the cloud, PECO can reduce the amount of time and resources required to run the same scenarios in parallel through hyperscaling. Smaller model runs can happen concurrently, allowing for additional model types to be optimized. Optilogic adapted to the unique, inherent complexity of PECO’s network.

|

Optilogic allows for shorter solve times, with more frequent model runs (with more model horizons), and is sophisticated enough to expand the model’s complexity and use of constraints, as PECO needed. Interested in learning more? Watch our video session below!